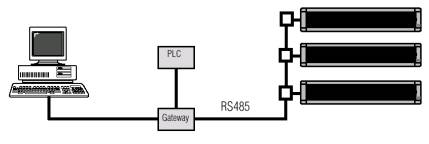

The Alpha Gateway Interface is used to connect Alpha LED Displays with Alpha Industrial firmware to the following industrial networks:

The following Alpha LED Displays are available with Alpha Industrial firmware:

The Alpha Gateway Interface maps Output and Input Data tables in the PLC to the Gateway Interface's Input and Output Data tables. Once mapped, the PLC, operating through the Alpha Gateway Interface, controls the following functions and operations of the Alpha sign network:

The Alpha Gateway Interface connects to Alpha signs via a multi-drop RS485 network. The network will support up to 32 drops (signs) before requiring a repeater. Alpha signs can be set to any address from 001 to 254 using the Alpha Automation software or by setting each sign's internal DIP switches. Programming Messages in Alpha Signs Alpha Automation software or Gateway Messaging software is used to create and store messages. Each Alpha sign can store up to 4,000 messages and up to 100 variables. If you are using RS485 connectivity to send messages to the Alpha signs, before you download messages from the software to the Alpha sign network, you must physically disconnect the Network Interface Module (Profibus, Modbus, DeviceNet) from the industrial network. After messages are downloaded, reconnect the Network Interface Module. If you are using RS232 connectivity to program messages in the Alpha signs, then you do not have to disconnect the Network Interface Module industrial network. Using RS232 connectivity, you connect one sign at a time to the Serial Port of your computer. There are three ways that Gateway network messaging can control messages on an Alpha sign:

The Output Data Table The Output Data Table mapped in the PLC to the Alpha Gateway Interface Input Data Table is used to control and execute all available operations of the Alpha sign network. Variable data corresponding to values in the Output Data Table and in the Alpha Automation or Gateway Messaging software may be included in any message. The Output Data Table consists of 32 words (64 bytes) of instructions from the PLC to the Gateway. The PLC's ladder logic invokes Alpha messages that have been programmed in advance using Alpha Gateway or Alpha Automation software. The Alpha Gateway reacts to the bits that are stored in specific registers of the PLC's Output Data Table and displays the appropriate messages and data on the Alpha signs. Messages may contain real-time production figures, alarms or actions that have to be performed, and PLC variable data such as counters, speeds and production totals. The Input Data Table The Input Data Table of the Alpha Gateway Interface consists of 16 words that are used in conjunction with the Output Data Table for the function that is being used. Various words are used to determine the status of a sign, the status of the Gateway, and the requested data. The Input Data Table gives feed back to the PLC. If there is a problem trying to communicate with a specific sign address (1 to 31), it will alert the PLC if there is a major fault. The Alpha Gateway Interface allows you to read currently running messages in a Alpha sign's queue. The message queue allows for up to 64 messages running at one time on any given sign.

|

|